Maintenance Articles

Lots of great content on this page. Here are your quick jump links to make finding it easier:

Spec Racer Ford Gen3 Maintenance Articles

Spec Racer Ford Gen2 Maintenance

Want more great Maintenance Articles? Sign up for our Newsletter.

Checklists

Checklist Before / After the Race Weekend

Torque Lug Nuts (55 ft-lbs)

Torque Axle Nuts (150 ft-lbs)

Check Floor Pan

Nut and Bolt Check:

Brake Caliper Mount

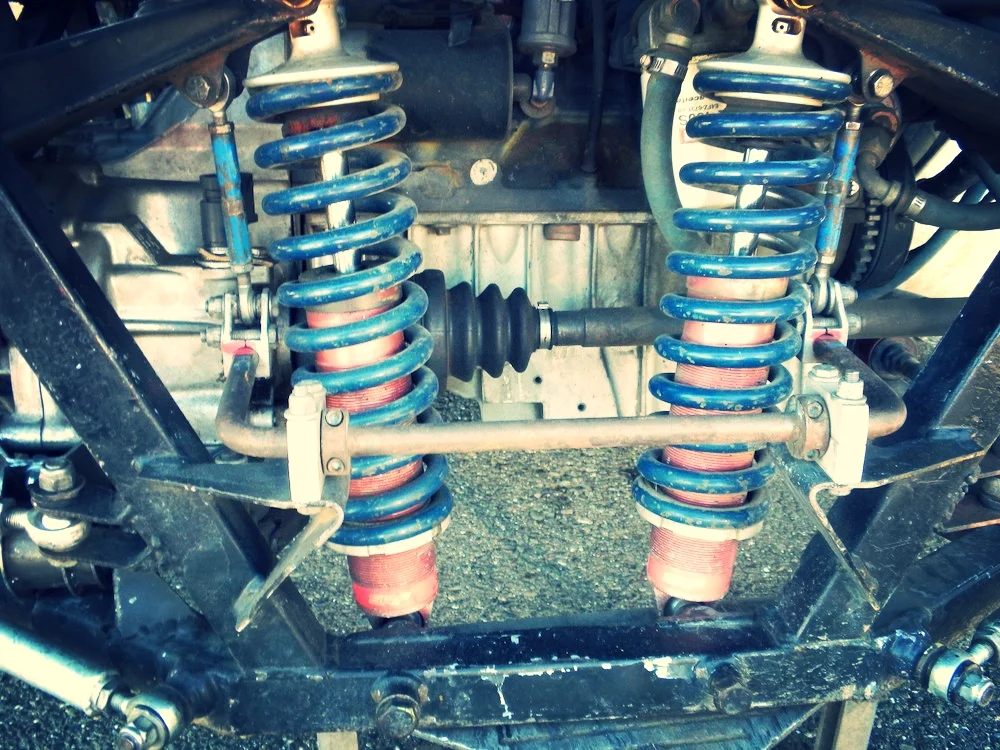

Lower Control Arm (LCA) and Jam Nuts

Rocker Bolts and Nuts

Check Cam Timing

Check Alternator Charging

Check Chassis for Cracks

Check Fuel Filter

Checklist Between Each Session / End of Day

Master Switch Off

Bolt & Nut Check:

Lower Control Arms

Upper Control Arms / Rockers

Torque Rear Axle Nuts: 150 ft-lbs

Torque Lug Nuts: 55 ft-lbs

Check Alternator Belt and Lower Bolt

Prior to Qualifying for SRF Gen2: Replace Air Filter (FRAM CA3660, Motorcraft FA1031)

Fluids

Fuel SRF Gen3: 20 to 40 % mix of 100 OCT unleaded with 93 / 91 OCT unleaded

Fuel SRF Gen2: 50/50 Mix Pump Gas 91 & 100 Octane Race Gas

Motor Oil Gen3: Red Line 30WT Race Oil / 5W30 (~4 Quarts)

Coolant: Red Line Water Wetter / Distilled Water

Gearbox Oil: Red Line MT-90 (~2.5 Quarts)

Brake Fluid: ATE Type 200 Amber / ATE Super Blue

Tripod & CV Joint Grease: Red Line CV-2 Grease

Rocker Arm Grease: Red Line CV-2 Grease

Ball Joint Grease: Red Line CV-2 Grease

Tie Rod Grease: Red Line CV-2 Grease

Annual Maintenance

Working in the shop at CSR Performance

Check Fire Extinguisher Bottle

Check Seat Belts

Nut and Bolt Check:

Brake Caliper Mount

Lower Control Arm (LCA) and Jam Nuts

Rocker Bolts and Nuts

Check Chassis for Cracks

Spec Racer Ford Tools

The Spec Racer Ford is built in the United States using Renault, Ford and Subaru parts, consequently there is a mix of metric and SAE fasteners on the car. Most suspension/chassis elements are SAE. While the motor and drivetrain are metric. This can be very confusing for the first few times. I grew up in Australia with metric tools so it is not immediately obvious to me which fractional wrench is needed. Here is a short list of recommended tools and some specialty Spec Racer Ford tools:

Specialty Spec Racer Ford tools:

Quick jack - getting the low car off the ground

Inner 5/8 crescent T wrench

Toe alignment bars

General Tools:

SAE and Metric wrench sets (ratcheting are useful in SAE)

1/4, 3/8 and 1/2 inch drive - SAE and Metric socket sets (short, deep and extensions)

Flare nut wrench for brake lines

AN wrenches (-6, -8, -10, -12)

Screw driver set

Cordless drill and drill bits

3/8 inch impact driver

1/2 inch impact up to 150 ft-lbs

Pop riveter and rivets

Compressed Air (Tank or small compressor)

Tyre Pressure Gauge (30 psi)

Castor gauge

Camber gauge

Pocket Steel Rule

Side cutter

Pliers

Wire strippers

Wire crimpers

Channel locks

Hammer

Rubber mallet

Safety wire and pliers

Duct tape

Oil filter wrench

Funnels

Gen3 Spec Racer Ford Conversion Manual

The SCCA Enterprises manual details the steps for doing the conversion from the 1.9 ltr to the 1.6 ltr including the ancillary equipment. It also has details on torque specifications, maintenance, spares and known areas to pay attention.

Spares List

You really don't need spares if you are racing with SCCA as there is great trackside support by the Customer Service Representative (CSR). The CSRs carry spares for cars and are present at the track for SCCA weekends. However, if you are running test days and track days without CSR support here is a short list of some items you might want.

Brake Pads - Enterprise PN: 801993

Vented Brake Rotors - Enterprise PN: 800065

Lower Control Arm Rod End

Gear box oil - 2-3 qt

Motor oil - 4 qt

Spark plugs - Gen2 NGK TR6 / Enterprise PN: 301041

Spare Aluminium for patching body work

Spare 1x Front Left/Rear Right & 1x Front Right/Rear Left Upright incase the wheel bearings fail

Alternator belt

Wheel Bearing - SKF B31 Tapered Roller Bearing / Enterprise PN: 200436

Upper Ball Joint - Moog K3082 Ball Joint / Enterprise PN: 236414

Tie Rod - Moog ES2287RL Tie Rod End / Enterprise PN: 261141

Gen3 Specific

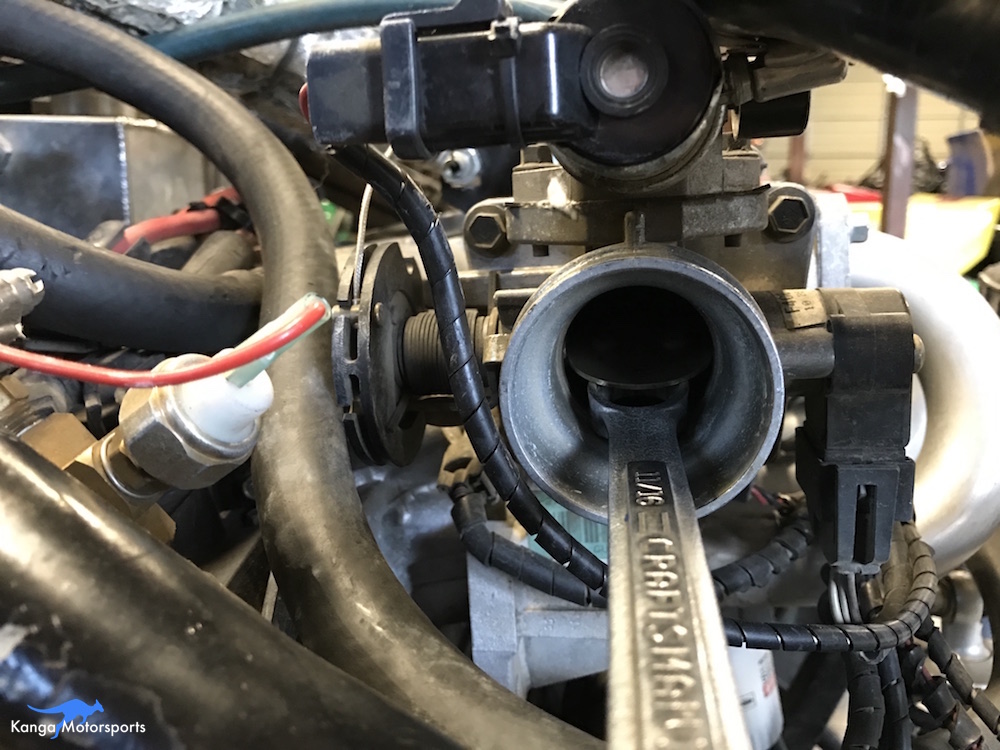

Spark Plugs – NGK LTR7IX-11 Iridium, Stock Number: 6510 Gap: .035” /.038 / Enterprise PN: G301041

Alternator Belt - Enterprise PN: G991412 / Gates K040440 Micro-V

Oil Filter - Motorcraft / Enterprise PN: FL-910 S

Ignition Relay - Enterprise PN: WM901006

Fuel Pump Relay - Enterprise PN: WM901006

O2 Sensor - Enterprise PN: G990504

Starter - Enterprise PN: G992701

Oil PSI Sending Unit - Enterprise PN: G980495

Fuel PSI Sending Unit - Enterprise PN: G980495

Air Filter - Enterprise PN: WM301020

Thermostat - Enterprise PN: G300999

Oil Filter Adaptor O-ring - Enterprise PN: 392499

Torque Settings

Lug Nuts: 55 ft-lbs

Rear Axle Nuts: 150 ft-lbs

Generic Torque Specs for Block /Head (Aluminum) fasteners:

6mm: 5 ft-lbs

8mm: 16 ft-lbs

10mm: 35 ft-lbs

Gen3 Specific

Flywheel: 65 ft-lbs

Clutch Cover: 18-20 ft-lbs

Intake Manifold Nut: 16 ft-lbs

Exhaust Header Nut: 30 ft-lbs

When replacing or refilling the Spec Racer Ford coolant system you need to make sure the all the air is bled out of the system before heading out on track.