Dang that don't look right? A tweaked ball joint or ball joint bracket can occur due to contact, an off track excursion or hitting the curbing hard. It is pretty straight forward to replace only requiring a few wrenches and simple tools. Ok lets get started replacing that upright bracket.

There is a separate guide to replace the Upper Ball Joint.

Tools and Equipment Needed

Ball Joint Bracket - Enterprise PN: 280095A

Two 1/2 inch wrenches (ratcheting will speed things up)

3/4 inch wrench

3/4 inch deep socket at ratchet

19mm deep socket

Impact driver (optional)

Breaker bar (optional)

Upright Bracket Replacement

Brake the lug nuts loose using the 19mm socket and breaker bar or impact but don't remove yet.

Jack the front of the car in the air and put it on a low jack stand.

With the front in the air, undo the lug nuts and remove the wheel placing it out of the way.

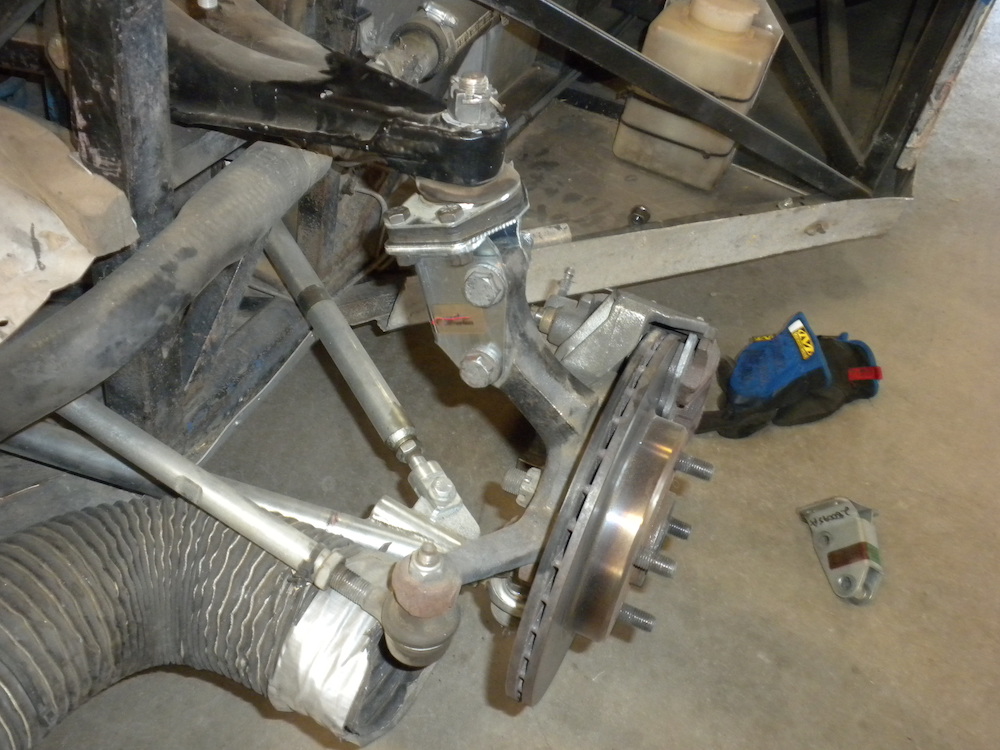

Using the 3/4 wrench, socket and impact, remove the lower and upper bracket upright bolts. The lower control will fall due to the weight of the upright and brake, support it to not bind the rod ends or stretch the brake lines..

Use the two 1/2 inch wrenches, undo the 4 upper bolts on the bracket separating it from the ball joint. Remove the tweaked bracket.

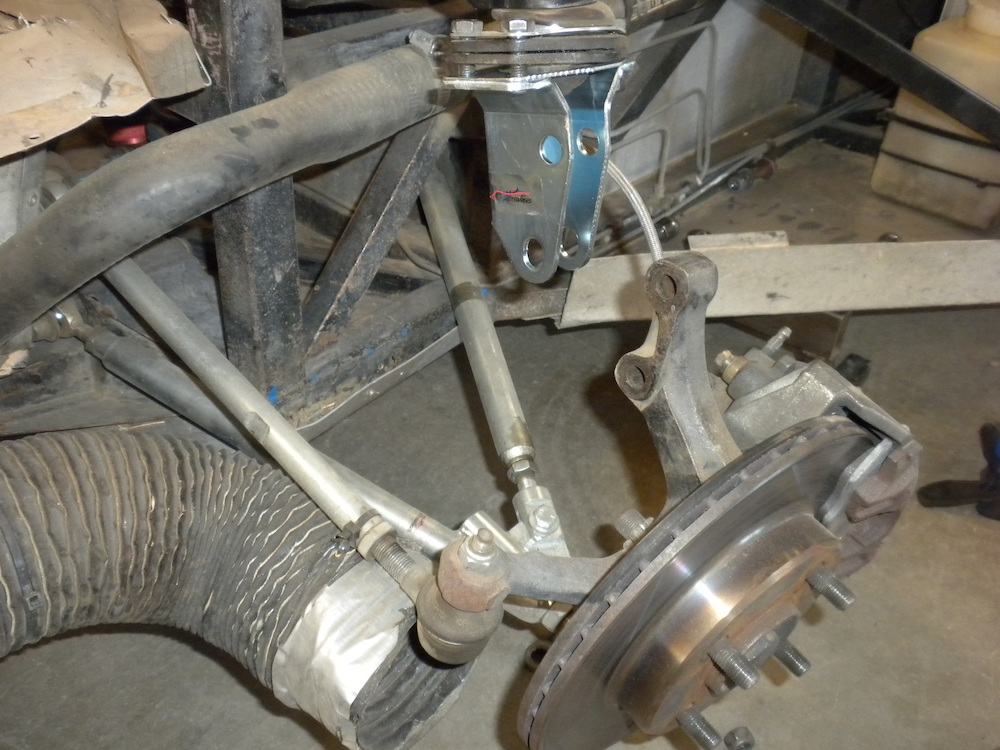

Place the new bracket (Enterprise PN: 280095A) up against the ball joint and slide one bolt and nut it in place to hold it there. You can then continue and put the remaining bolts in place and torque all four down. Make sure you include the lock washers.

Lift the upright assembly into place and slide the upper bolt in and nut in place. The nylock nuts can get worn out over time if it looks old and tired replace it. Then slide the lower bolt in. Tighten both bolts in place using the 3/4 wrench, socket and impact.

Install the wheel back onto the hub and torque the lug nuts to 55 ft-lbs.

You should now check the alignment on the car as the caster, camber and toe may have changed depending how the bracket and ball joints were tweaked.

Other Maintenance Articles

We decided to replace the old bent and misshaped suspension rockers with the new lighter and stiffer tubular rockers. The step by step guide should make it easier for those attempting the work themselves.

A critical part of any cars suspension is the dampers also known as shock absorbers. The seals wear out over time requiring a removal, rebuild and re-install.

A guide to installing new race car harnesses into the Spec Racer Ford, including how to re-web for different end fittings.

Unfortunately the Fuel Cell bladders do not last forever and over time they will start to leak. This step by step guide should make it easier for you to tackle the job.

A step by step guide for replacing the Tie Rod on the Spec Racer Ford. The same process applies to most production and race cars.

One of the easiest piece of maintenance for the Spec Racer Ford Gen3, draining the Breather Bottle.

A step by step guide for replacing the upper ball joints on the Spec Racer Ford. The ball joints are a maintenance item that is not often required except after a few seasons.

The Spec Racer Ford Gen3 uses a reusable air filter that can be cleaned and refreshed with a new oil coating.

A quick health check of the Spec Racer Ford Gen3 engine can accomplished by performing a compression test.

Changing the oil filter on the Spec Racer Ford Gen3 is made difficult by the interference of fuel filler hose. This guide should help keep the mess to a minimum.

Servicing the half shafts can involve repacking the grease to prolong their life or replacing the CVs and Tripods that have worn out.

To ensure smooth operations of the brake calipers it is a good idea to replace the pins and bushings as they wear over time.

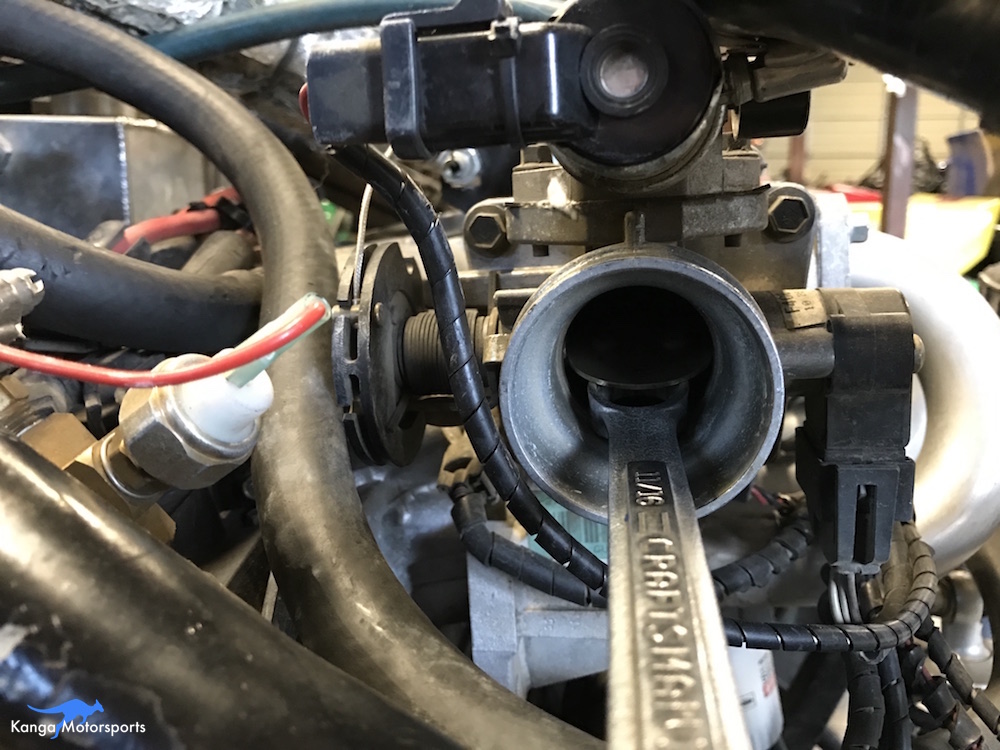

If the fuel injectors are sticking swapping the injectors is easier if you remove the fuel rail.

A great video produced by MidWest Spec Racer shows how to install the updated 5th gear on the Spec Racer Ford Gear Box.

The seat doesn't move on a Spec Racer Ford. To accommodate different height drivers the pedal assembly moves fore and aft.

Part of the annual maintenance program is to replace the Spark Plugs. You need to remove the alternator to access Spark Plug #1.

The fuel filler hose dries out and cracks with time. Replacing the hose just requires a little finnese to remove and then position the new hose in the right spot.

Swapping out a throttle cable just takes a little finesse feeding it through the chassis and a handy helper to ensure you are reaching full throttle.

The stress of racing puts a lot of load on the wheel bearings especially with the new stickier tires. To change out a wheel bearing you need a press.

When replacing or refilling the Spec Racer Ford coolant system you need to make sure the all the air is bled out of the system before heading out on track.