Coming into the 2017 season I was very excited. The damaged body work from year mean't we could update the car with a new livery. In the off season we brought on some fantastic partners and addressed maintenance and minor issues on the car.

Test Day

Arriving early at Thunderhill Raceway Friday morning I was ready to get out on track and put in some fast times. The morning starts with registration for the test day, getting your car sticker and wrist band.

After that I helped unload the car and get it prepared for the first warm up session of the day. The warm up is a short session but provides a good time to scrub in the brakes and set tire pressures. A test day typically involves 4-5 session of 20 to 30 minutes each. For this test day we would have 5 session of ~25 minutes.

The first full session was good. It felt fantastic to be back out on the track. The tires felt good and I was able to put in some decent initial times. I still was a couple seconds of my best time and there was some work to do. Future sessions, I planned to focus on different areas including smoothness, end of braking techniques and Turns 1, 6 and 11 were I knew from data I could gain more time.

The second session was ok, but I lost the alternator belt part way through and had the warning light come on. I pulled back paddock and looked over the car. There appeared to be no immediately obvious issue. We had previously replaced the alternator midway through last year. Looking it over everything seemed to be ok so I reinstalled the belt and used the adjuster to make it a little tighter.

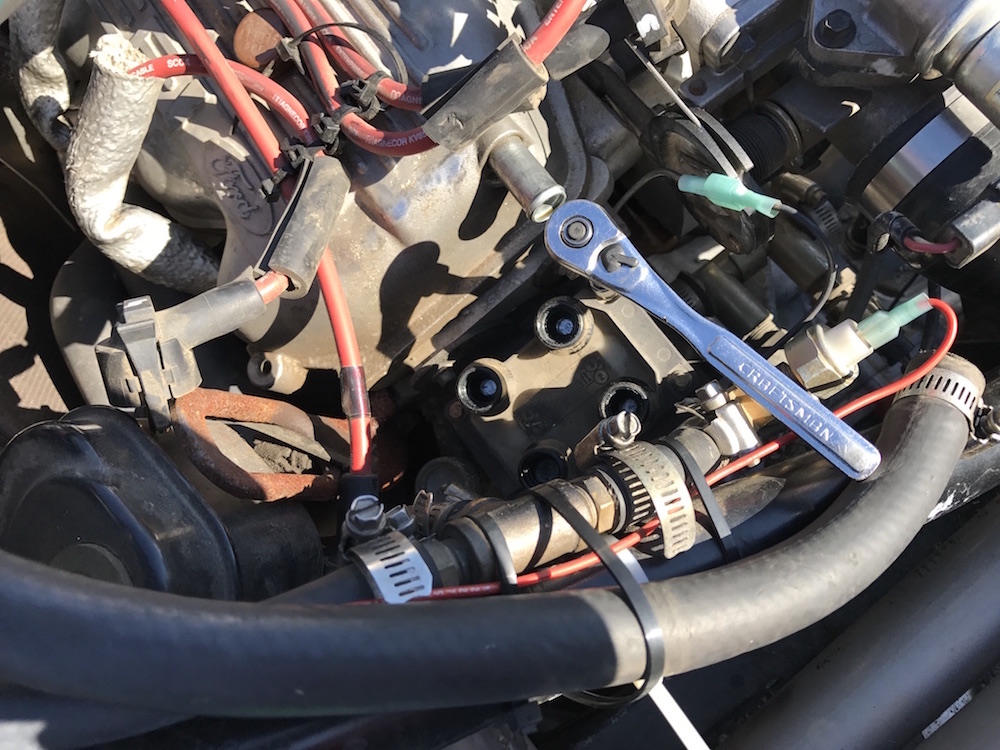

Going out for the third session I again lost the alternator belt early on. There was obviously a much bigger issue that needed to be addressed. I pulled in early and got to work. Looking closer without the belt on and wiggling the armature it appeared the bearings were bad in the alternator. With limited time between sessions I sourced a new alternator and tried to install it before the next session.

Getting it in the car just in time I started it up and the little alternator warning light beamed at me mockingly. The charging circuit wasn't working. Putting a meter on the battery confirmed it was not charging. Looking closed I had accidentally switched the two smaller terminals on the alternator. In my haste to get it done in time, I had missed the details. I was not able to take the track for the next session.

I proceeded to remove the alternator again and reinstall it, this time switching the two wires and firing up the car. Everything worked great, no evil light and the car was charging.

I got out for the last session of the day and everything ran fine. I was able to focus more on driving and working on my test day goals. By the end of the day the issues had cut into my limited run time.

My race car needed it's annual technical inspection in order for it to compete for the rest of the season. Big thank you to the SCCA Tech Inspectors that opened up in the evening so we could get our car inspected before the morning rush. The Tech Inspectors look for safety items and ensure the car is in good condition, suitable for racing and meets the class rules. Things they look for include the expiration dates on the harnesses, excessive suspension or steering play, kill switch operation, brake light and a charged fire system.

With my old helmet expiring this year as it was Snell 2005 certified, I also needed to get my gear inspected. Big thank you to the extra SCCA workers that performed gear checks even while the sun was getting low. In short time they found the needed certification labels on the race suit, shoes, gloves, arm restraints, helmet and head and neck device. They also checked to ensure there were no holes and everything is in good usable condition to keep me safe. Insert the requisite stickers in my log book and I was cleared for racing.

After a long and tough day I was ready to retire to my hotel room at Super 8. I was lucky enough to get one of the race car themed room, so I could dream about racing while I got some rest.

Practice Session

Arriving early in the morning I checked over the car and got it prepared for the day. Unfortunately, I discovered a worn wheel bearing on the front left side. Regrettably I wish I had found it the night before, lesson learned.

Replacing a bearing means disassembling the left corner to remove the upright, pressing out the old bearing and installing a new one. Taking the front corner off and replacing the wheel bearing took too longer than we thought and required the use of a press. Regrettably I missed the short morning practice session.

Qualifying 1

With the previous issues all resolved the car was prepared for Qualifying 1 and after all the work on the car, I was ready to turn some more laps. I put in some laps and was able to put in an ok time of 2:05.933.

Not very fast and still far slower than my personal best of 2:02.931. It was enough to qualify me 7th out of 10 in class. I was still leaving a lot of speed on the table.

SFR SCCA Race 1

I was really looking forward to Race 1, it had been several months since I had last raced and I was looking forward to going wheel to wheel again. The racing was fantastic. The start was full of action with cars going 2 wide through Turns 1 through 5 before the field spaced out in Turn 6. I was at the back of the lead pack and struggled to keep up. I could keep them insight but couldn't catch them. My best lap time was 2:05.245 still well off my usual pace. But by the end of the 13 lap race I had gained 2 positions moving up from 7th to 5th place.

Qualifying 2

After thoroughly checking out the car the night before I was ready for the Sunday Qualifying and Race 2. I had a terrible qualifying session the car had developed a misfire and it also cut out and died multiple times. After the session I checked the electrical connections looking for anything loose or shorting out that would indicate a misfire or motor cut out. I tiddied up any wiring that I thought might be marginal and checked the plug wires, ground wires, alternator and the ignition coil. I found a dirty terminal in the ignition coil and cleaned up the corrosion. That might have explained the misfire but it still was not clear what caused the cutting out of the car.

Hardship Lap

With the car wiring tidied up and the bad terminal on the ignition coil addressed I went to see if I could get a hardship lap before the race. Talking with Tech, Race Control and Grid I was able to get a hardship lap right after lunch and a few sessions before the race. Some issues you can't find until the car is at speed and the drivetrain under load. A hardship lap allows a competitor to do a quick one time around the track and pull into the pits to ensure any issues are addressed before their next session. As I left the pit lane the car seemed fine but sadly turning into the first corner the car died. Then died again later in the lap. I defeatedly limped home to the pits unsure of where the issue might be. With only about an hour left to fix the issue we went over the car doing the wiggle test on all the obvious wires while the car was running. Since the car was just dying and there was no longer a misfire it pointed to an electrical short or fuel. We checked the fuel filter and fuel pressure and it looked good. We searched over the car for shorts or loose grounding wirings but couldn't find anything. Inspecting and operating the master switch it worked fine. With little time remaining we decided to change both relays and see if that made a difference.

SFR SCCA Race 2

The race start was a little chaotic a few cars got off really well while others were slow. This resulted in some bunching up of the field and going several cars wide into turns 1 and 2. I got sandwiched between two cars either side and the one on the left came over and lightly bumped my front corner. I was a little concerned the radiator might have been tagged. Checking the gauges and looking at the temperatures everything seemed ok, but continued to keep a close eye on them.

The cars quickly came into single file as we raced. This time I was able to stay with the front runners, gaining ground in some sections of the track and losing a little in a few turns. Good notes for the next race on where to improve.

Staying with the lead pack they raced back and forth with a few lead changes and shuffling. In the back of my mind I was thinking the relays must have fixed it and everything was good. Unfortunately coming out of Turn 6 right on the bumper of Joe in the #9 car on lap 4 the car died. I lost all power and was just coasting as I saw the cars pull away into the distance. Damn! The problem was still there. I got the car started back up again and got down to business trying to catch up. Maybe the problem was intermittent? I had a few laps clean laps maybe it would be fine? Nope. Coming out of turn 11 the car stuttered again. Then again in Turn 9 on the next lap. At this point Frank in the #4 was close behind. I decided to pull into the pits rather than risking an incident with other cars closing behind me.

I limped the car home into the pits and parked it. Disappointment set in. I didn't get to finish the race. The engineer in me thought hey, maybe I can find it now in the pits since it was repeatable on track. Removing the rear body work, I fired up the car and did the old wiggle test on the wires and looked for anything that could be wrong. It passed the wiggle test and nothing was immediately obvious.

Sadly I had to pack the car into the trailer not knowing what had caused the issue. In between the next race we will have to work to get it sorted. Part of racing is the struggle that happens off the track. I learnt a lot over the race weekend especially about troubleshooting and diagnosing the car.

Thank you to all those that made this weekend possible including friends, family, sponsors and partners, particularly our title sponsor for this race Millennium Engineering and Integration Company. Special thanks to Ric at CSR Performance for helping me with the car, trouble shooting and trying to diagnose the electrical issues. Big thank you to all the SCCA workers and volunteers that put in the hard work and long hours so that we have the opportunity to race.

The next race is only a few weeks ago!

After a long time away from the track we return to the Historic WeatherTech Raceway Laguna Seca with SCCA San Francisco Region. A fantastic weekend with great friends and lots of close racing.